>

Untitled sculpture, Mary Shaffer, fused and slumped industrial sheet glass, 1975

As part of the 50th Anniversary celebrations in honor of the 1962 Toledo Glass Workshop, the Washington Glass School blog is looking the heritage of the art movement. This is the second part in an historical overview of how fused glass (aka kiln-formed, or warm glass) fits into the contemporary Studio Art Glass Movement. Much of the information was based on published writings by Martha Drexler Lynn, William Warmus & Beth Hylen, Richard LaLonde, Dan Schwoerer & Boyce Lundstrom and from the Corning Museum of Glass library.

Clipped Grass, Mary Ann “Toots” Zynsky, green tinted fused and thermo-formed glass threads, 1982

Antique collecting in the 1960’s brought about a renewed interest in stained glass. Cities such as

The modern stained glass movement, started by mimicking the traditional work evolved into a very diverse art form. Boyce Lundstrom, one of the founders of Bullseye Glass Company wrote:

“Our experience in the glass world pointed to a need for more colored sheet glass for the stained glass industry…(I) began working with glass in 1965, when I joined the new glass program established by Dr. Robert Fritz that year at

In Dr. Fritz’s program I learned to control all phases of the process of making finished blown objects. We built glass melting equipment, calculated and melted batch, formed the glass, and carried out all the cold working processes for finishing the annealed work. After my graduation from

Two of those artists were Ray Ahlgren and Dan Schwoerer, who were partners in a glass blowing. (Ray Ahlgren started his glass career in

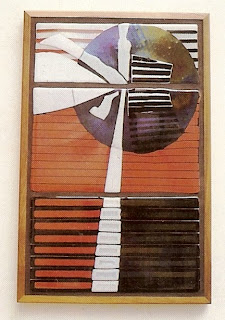

Ray Ahlgren, fused glass tiles, plywood, 1982

Said Boyce: “For the next four years, the pressing demands of an infant company consumed all of my time. In 1978 I began designing independent stained glass panels, executed for me by more capable craftspersons. Since, at Bullseye, we produced mixed colors of glass daily, and had control of the formulas, it seemed a foregone conclusion that we could make sheet glass with similar coefficients of expansion.

Boyce Lundstrom, red glass fused bowl, 1979

The thought process went something like this: if sheet glasses had the same coefficient of expansion, they could be cut into shapes and fused together. So, I started experimenting in 1979 or 1980–I don’t know exactly when because the process was slow at first, fraught with many failures and just a few successes. If there was one memorable breakthrough, it was the application of the method of testing for stress with a polarimeter (from glass blowing) to glasses fused to a clear sheet glass with a constant coefficient of expansion.

When making sheet glass it is not important to have a constant coefficient of expansion among all the glasses. Single colors can all be different and mixed colors only have to be within one or two coefficient points of one another. In glass blowing it is not uncommon to use glasses together that vary in coefficient of expansion by four or five points, because the casing process holds the glass together. But when fusing glass flat, the glasses must be very close in coefficients. Establishing a clear glass as a constant, and then formulating the melt for all colors to fit that constant, made the contemporary glass fusing movement possible.

The ability to fuse glass, by taking it through the complete process of heating, holding and annealing, then checking the finished results with an accurate test, really stimulated my dreams of unlimited possibilities. I saw kiln fired glass as the wave of the future, providing freedom for all those who would like to be freed of the lead lines! Tiles, windows, bowls, sculptures, and building facades could all be made with fused sheet glass… By 1981, I became adamant about producing glass for the fusing market at Bullseye Glass. My remaining partner, Dan Schwoerer, supported me in my one-man campaign to make fusing available to everyone. During the next few years we succeeded in making available a line of fusing compatible glasses. By 1983 we were teaching fusing in diverse parts of the world, establishing a line of products and working with kiln manufacturers to get kilns designed for glass on the market.”

The influence by the hot glass education and artwork by the artists that came from the universities now teaching glass artwork outlined the directions that warm or kiln-formed glass would take. In the late 1960s there was the emphasis on technology and education. The glass artwork was part of broader international craft movement of the 1960s in which clay, fiber, wood, and metal are used for creative expression.

Gyes Arcade, Christopher Wilmarth, flat and curved plate glass elements, 1969

In 1969, glass was rarely seen in contemporary art, especially in large-scale sculpture. However, the American Studio Glass Movement was gathering national momentum. Many studio glass artists looked at contemporary sculpture, such as Gyes Arcade, for inspiration on how glass might be treated artistically.

At the 1972 National Sculpture Conference in Lawrence, Kansas, Harvey Littleton introduces his phrase “Technique is cheap” that continues to influence artists. The dichotomy between the sculptor in search of form (the “technique is cheap” attitude) vs. the craftsman striving to create a perfectly executed functional object is a strong motivation for many artists.

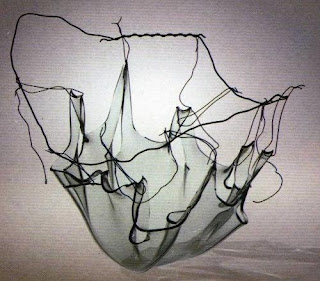

Bowl #2, Mary T Warren, glass, wire, 1978