>

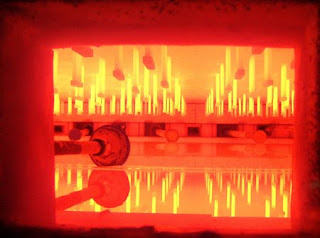

| M L Duffy checks for tin side as he creates the cast glass for Safeway supermaket’s Bethesda public artwork. |

|

| “This feels like float…” |

|

| Ow. |

Float Glass Fun Facts

>

Molten float glass floating atop liquid tin.

Since the earlier posting about BE’s glass forming process, many have asked us about how float glass is made so smooth. The answer is due to the manufacturing process.

The first advances in automating glass manufacturing were patented in 1848 by Henry Bessemer, (of steel-making fame), who developed a steelmill-like, but very expensive process to produce a continuous ribbon of flat glass force under heat between rollers. Another old method formed large sheets of plate glass by casting a large puddle on an iron surface. Both of these processes required secondary polishing.

Then in the 1950s, Sir Alastair Pilkington and Kenneth Bickerstaff created the first successful commercial application for forming a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. By floating on the bed of tin, the glass sides are smooth and flat, however the glass does pick up a tin residue – which often needs to be addressed when kilnforming.

Not as motivational as Bullseye Glass’ Mitchell Schou’s wicked dance moves – but educational.

Click HERE to jump to an industry video about the float glass process.