>From Paragon Kiln’s Arnold Howard-

Repair bulging elements. Please see Paragon’s video before attempting the repair.

Repair bulging elements. Please see Paragon’s video before attempting the repair.

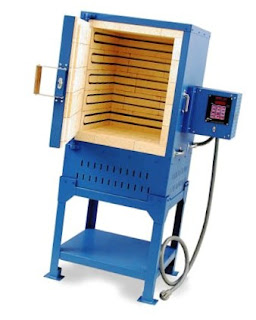

HOW TO GET THE LONGEST LIFE OUT OF YOUR ELEMENTS

The lower the kiln temperature, the longer the heating elements will last.

Long holds at high temperatures add wear to the elements. Use only as much hold time as you actually need.

Contact with foreign materials such as ceramic glaze, glass, kiln wash, and glass separator can ruin an element. Do not coat the kiln walls, lid, or roof with kiln wash; it can flake off into an element groove and burn out an element.

Occasionally vacuum the element grooves. A build-up of dust can overheat an element and reduce its efficiency.

Repair bulging sidewall elements. Elements that bulge out of a sidewall groove are susceptible to breakage since elements are brittle after they have been fired.

Avoid reduction firings (burning carbonaceous materials) in an electric kiln.

When replacing elements, always use new element connectors, and tighten them to your kiln manufacturer’s specifications. Loose element connectors burn out.